CNC-machine tool

Thanks to its CNC-machine tool Socoges is able to effectuate a wide range of works. This machine is composed of three defined axis, a work space with x=1500 mm, y=870 mm, z=900 mm and the following elements:

It is possible to effectuate all the piercing operations and the two-and-a-half-axis milling ones.

The work cycles can be programmed both manually (directly on board) and through a CAD/CAM software installed on an external PC.

This software is HyperMill is totally integrated into the SolidWorks 3D context.

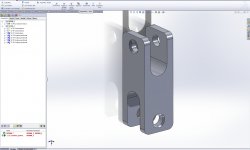

Here below is an example of work, together with its operations list.

An ISO format file is sent to the machine after it has been post processed by the software in the machine language in order to be recognised by the Sinumerik 840D.

- Work holding table: 360° turnstile with a 1020mm X 870mm workable surface, a 0.001°minimum angle of division and a 2500 kg load limit;

- Accuracy and precision: Positioning error in linearity 0.01 mm, repeatability 0.01 mm;

- Feed motion: min speed in Jog 5000 mm/min, max speed in Jog 20000 mm/min;

- Horizontal spindle: reamer ISO 50, continuous speed variation 20-3000 rpm, continuous power 22 kW, double speed range;

- Multiple tool holder: 40 tools available at once;

- Automatic shaving transport;

- Overall weight: 14,5 qt. .

It is possible to effectuate all the piercing operations and the two-and-a-half-axis milling ones.

The work cycles can be programmed both manually (directly on board) and through a CAD/CAM software installed on an external PC.

This software is HyperMill is totally integrated into the SolidWorks 3D context.

Here below is an example of work, together with its operations list.

An ISO format file is sent to the machine after it has been post processed by the software in the machine language in order to be recognised by the Sinumerik 840D.